Remote Tank Monitoring

Home » Mechanical Services » Remote Tank Monitoring

Automate the Efficient Operations of Your Liquid Fat System

Feed Energy is dedicated to innovation all the way down to the people that supply our products, by ensuring feed mill managers are stocked sufficiently and efficiently. Our remote tank monitoring services are designed to maximize your operation’s productivity by monitoring:

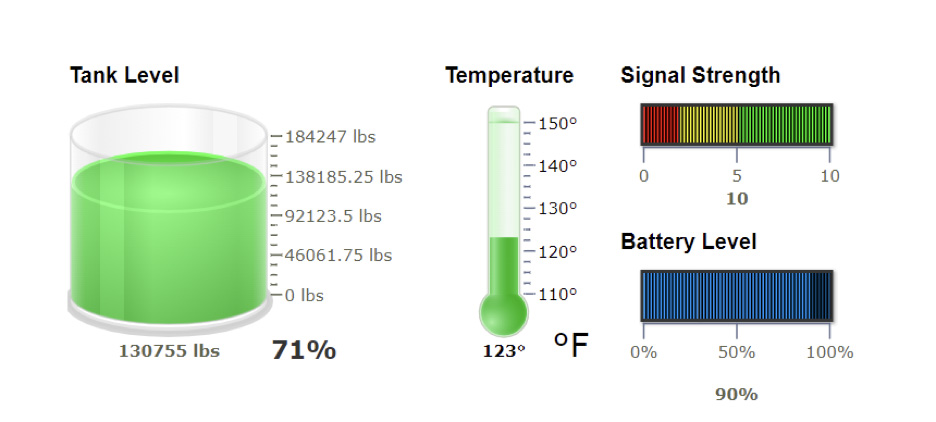

Tank Volume

By keeping an eye on tank levels, Feed Energy can automatically dispatch a truck to your mill location when your supply is low–saving you time on the job and time on the phone in placing new orders.

Tank Temperatures

Feed Energy’s remote tank monitoring assures consistent flowability and proper handling of product by tracking tank temperatures. When liquid fat gets too hot or too cold it causes issues from binding, to settling, to lack of viscosity, which necessitates expensive reparation. Feed Energy notifies feed mills to make temperature adjustments to maintain ideal flowability and avoid these costly repairs.

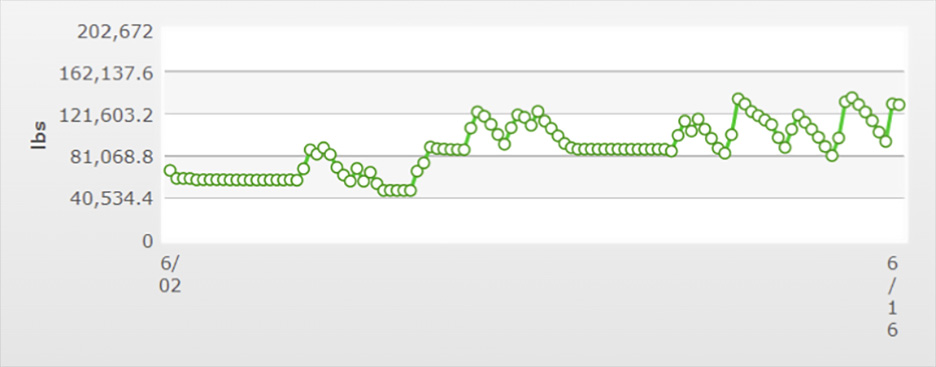

Historic Data

Ensure your needs are met well before you run out of product with Feed Energy historic data tracking. By tracking inventory levels and replenishments over time, Feed Energy is able to better predict which feed mill locations may need loads at which times.